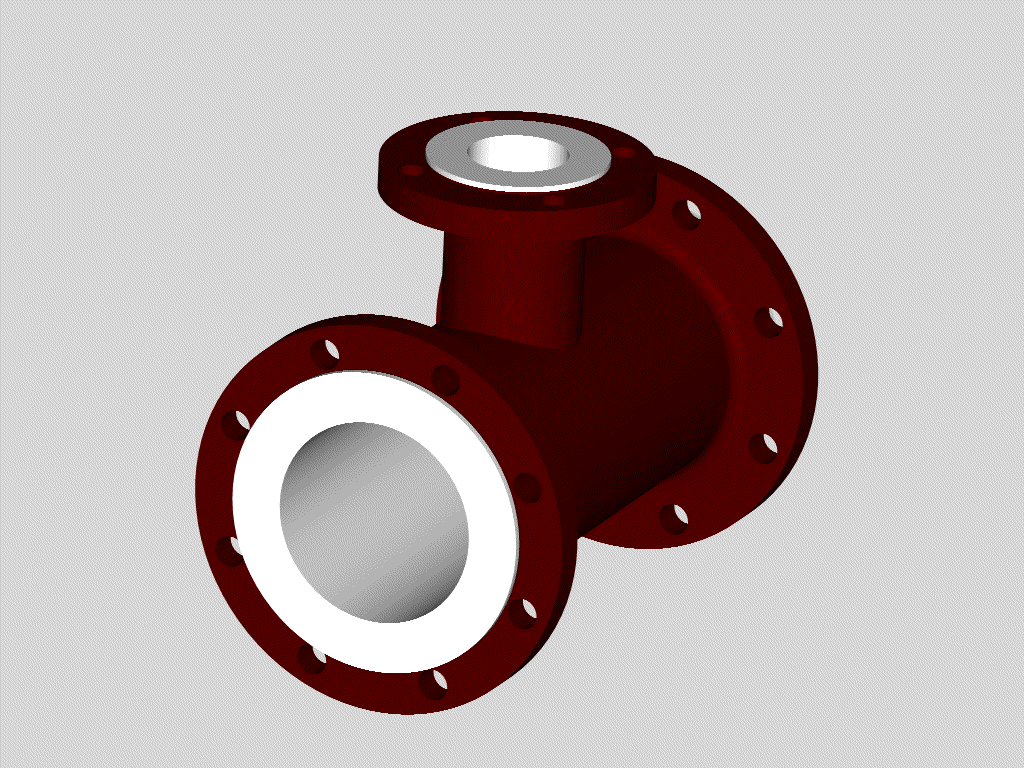

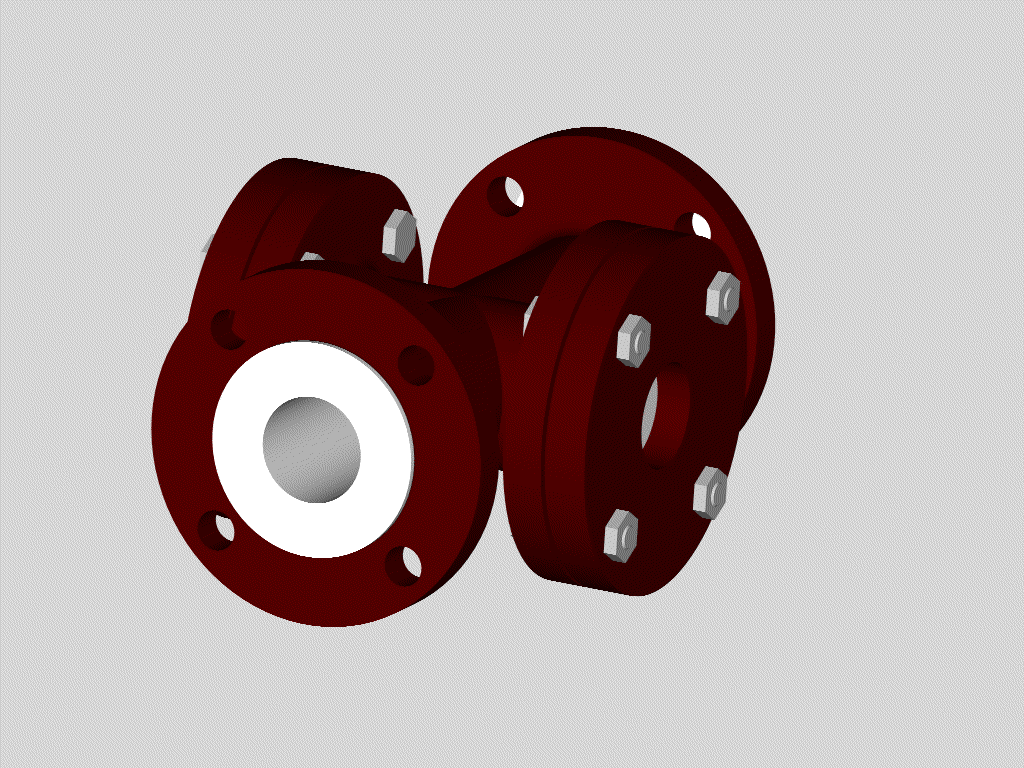

SHELL – DI Casting As per ASTM A 395 Gr 60-40-18/ Grade WPB/ WCB

Drilled to ANSI 150#/300#, DIN/BS/IS/JIS/GB on demandLining : By Injection Moulding Process by using Virgin

PFA : As per ASTM D 3307

FEP : As per ASTM D 2116

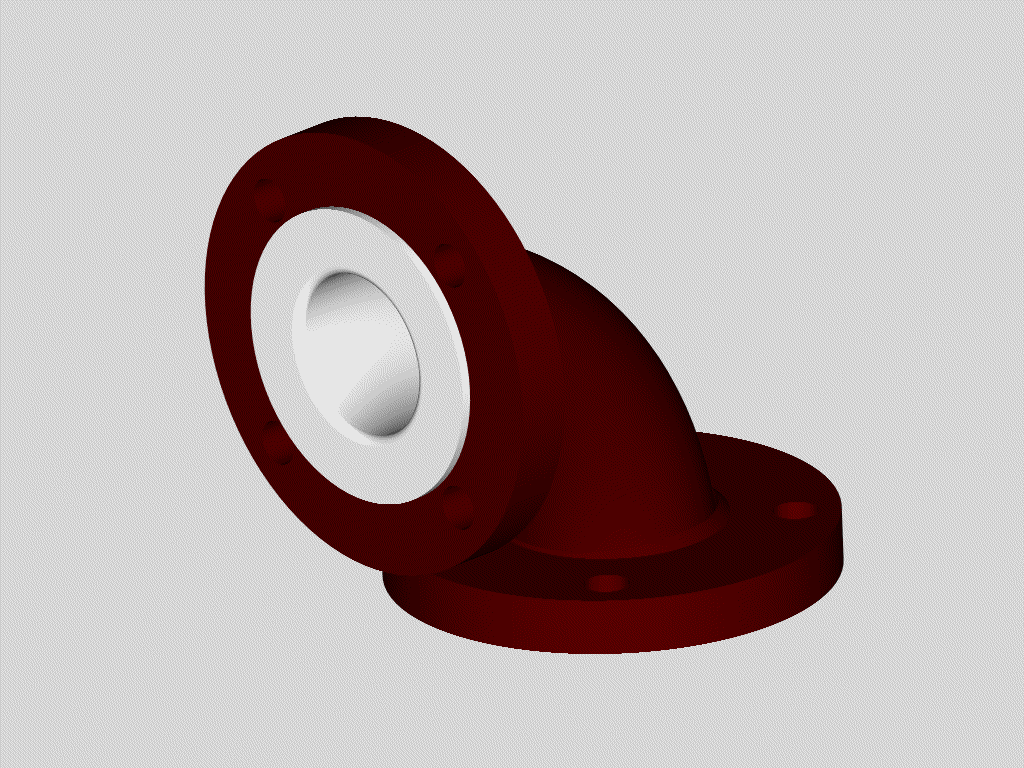

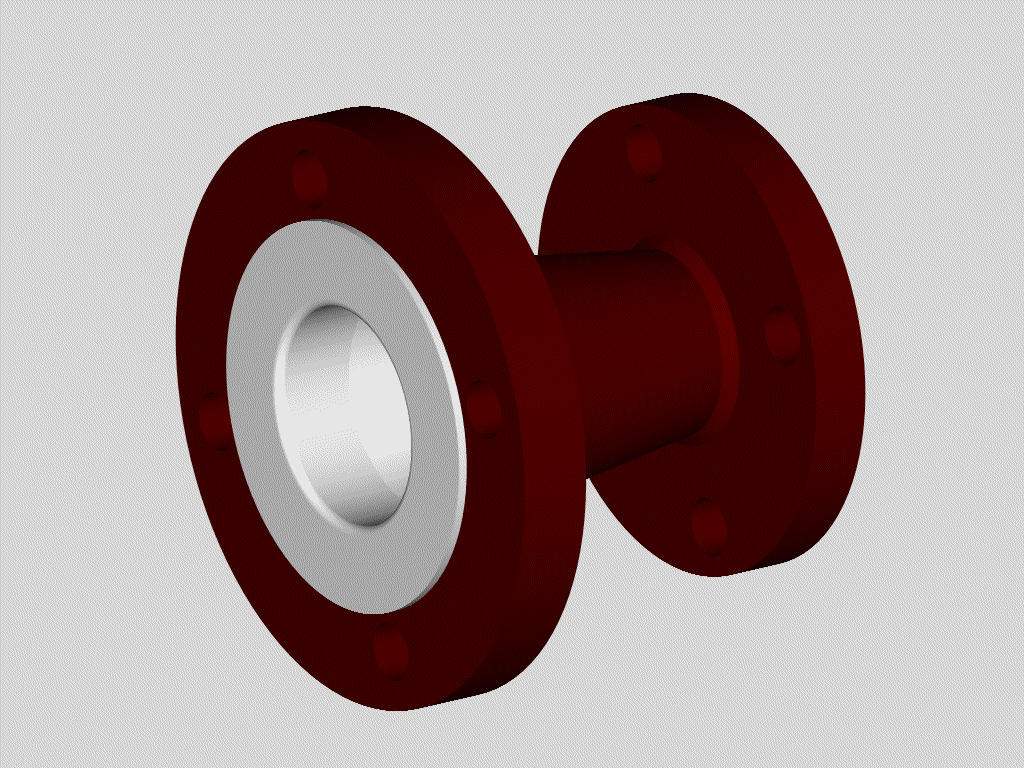

SHELL – DI Casting As per ASTM A 395 Gr 60-40-18/ Grade WPB/ WCB

Drilled to ANSI 150#/300#, DIN/BS/IS/JIS/GB on demandLining : By Injection Moulding Process by using Virgin

PFA : As per ASTM D 3307

FEP : As per ASTM D 2116

A concentric reducer is used to join pipe sections or tube sections on the same axis. The concentric reducer is cone-shaped and is used when there is a shift in diameter between pipes. Unlike eccentric reducers, concentric reducers have a common center line. Concentric reducers are useful when cavitation is present.

FOR TECHNICAL SPECIFICATION

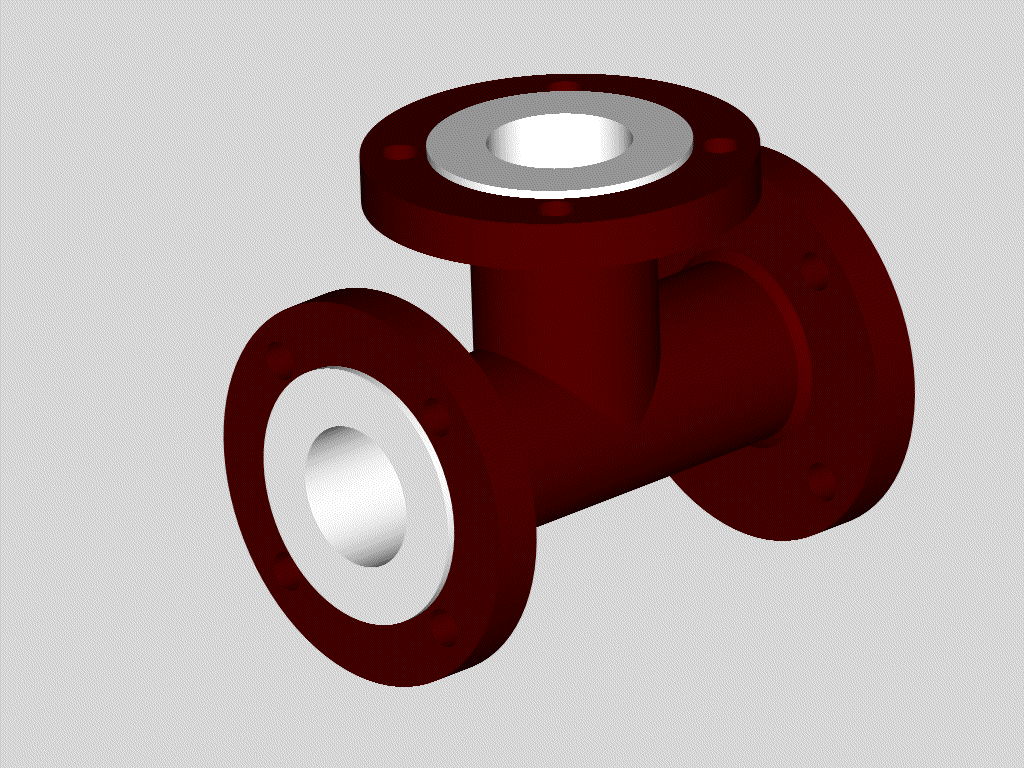

An equal tee, otherwise called straight tee, is a buttweld fitting used to branch a pipeline, or any other pipework, at 90 degrees. A pipe tee is defined “equal” when the bore size at the run and branch sides have the same diameter. An equal tee is, therefore, used to connect two pipes of the same nominal diameter.

FOR TECHNICAL SPECIFICATION

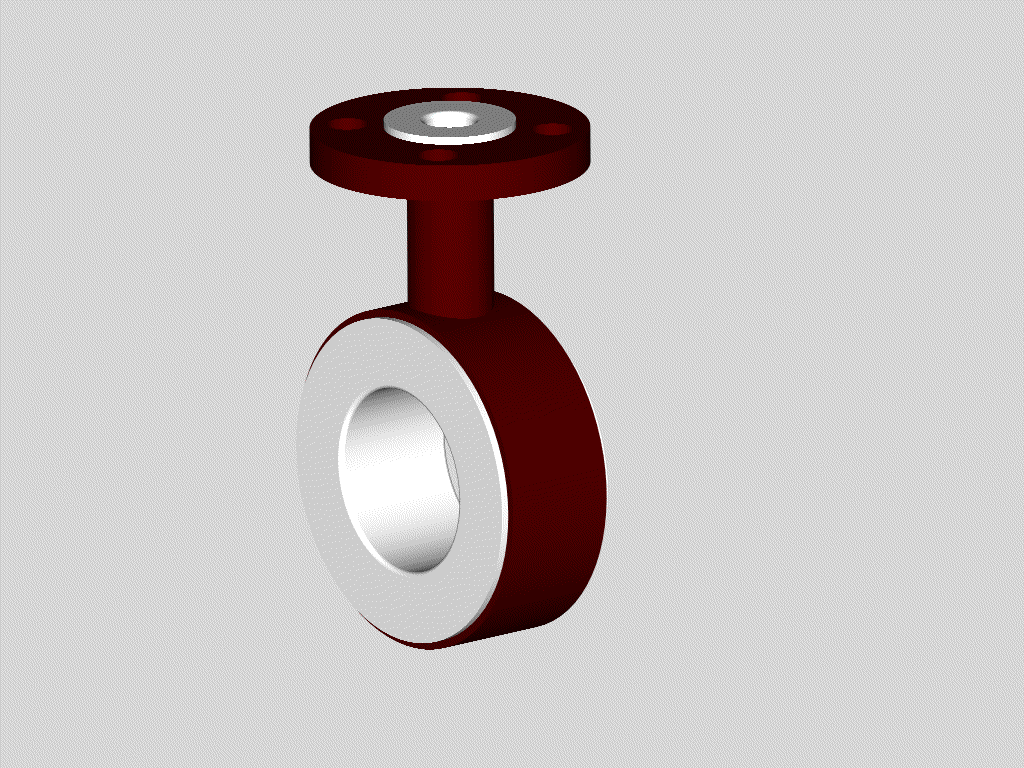

SHELL – DI Casting As per ASTM A 395 Gr 60-40-18/ Grade WPB/ WCB

Drilled to ANSI 150#/300#, DIN/BS/IS/JIS/GB on demand

Lining : By Injection Moulding Process by using Virgin

PFA : As per ASTM D 3307

FEP : As per ASTM D 2116

Instrument tees are designed to allow the installation of pressure gauges and other similar instruments without introducing a dead-leg. Manufactured in 316L stainless steel, instrument tees are available with either clamp or weld ends.

FOR TECHNICAL SPECIFICATION

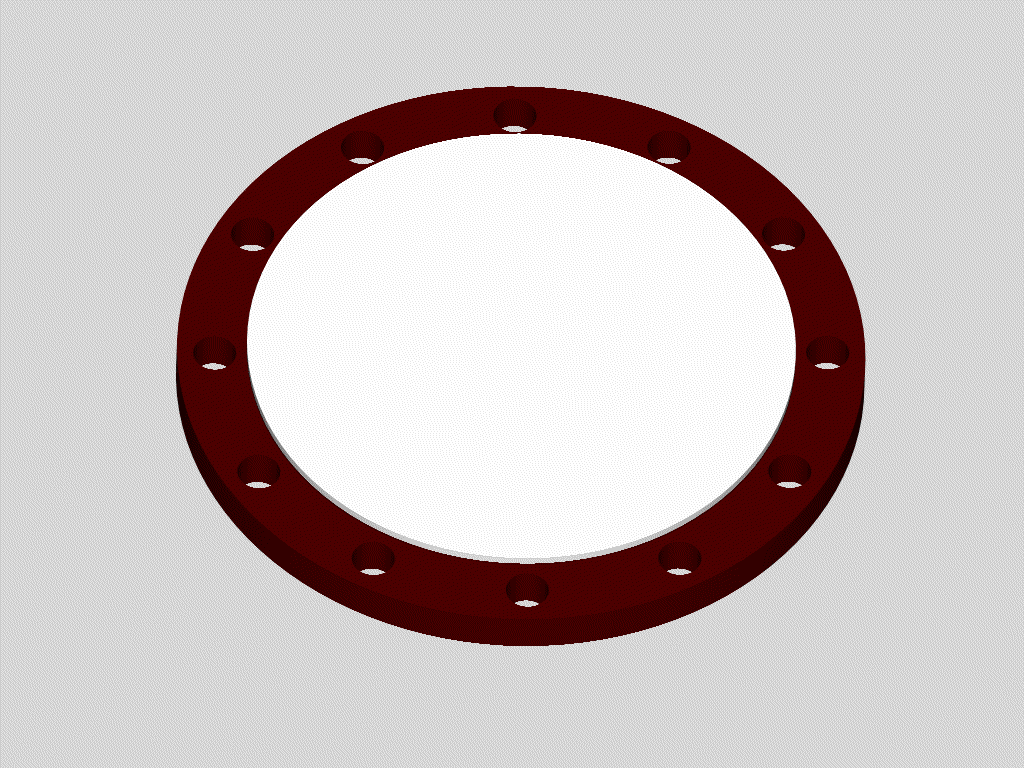

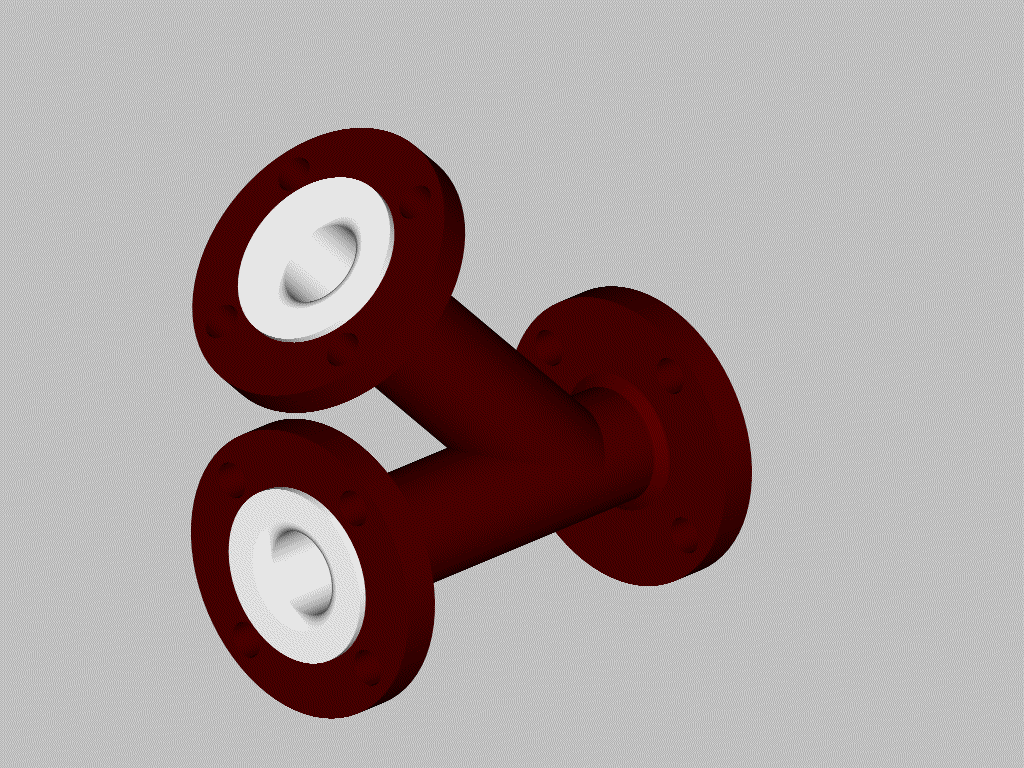

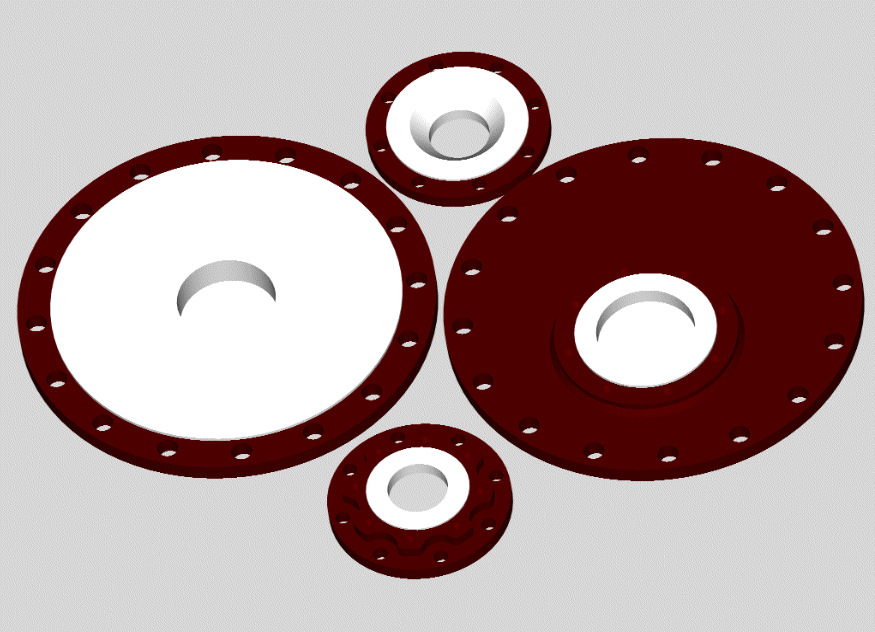

Reducing flanges are a specialty flange that are most often used on projects that require the fitting together of different sized pipes. A reducing flange consists of a flange with one specified diameter having a bore of a different and smaller, diameter.

FOR TECHNICAL SPECIFICATIONShell as per ASTM A 234 Gr WPB Sch 40 from 25 NB to 200 NB. Elbow will have both side fixed flange. Both side loose/One side fixed and one side loose flange will be supplied on demand.

Flange : ASTM A 105/ IS 2062

Drilled to ANSI 150#/300#

DIN/BS/IS/JIS/GB standards on demand.

Liner : Manufactured by Paste Extrusion Process By using Virgin PTFE as per ASTM A 4895